|

Dongguan Songhu Plastic Machinery Co.,Ltd

|

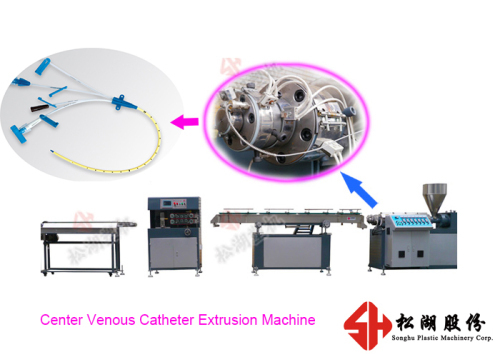

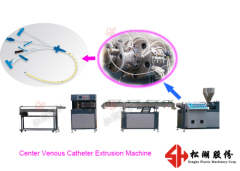

Multiple Lumen Center Venous Catheter Making Machine Mass Production

| Price: | 30000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Multiple Lumen Center Venous Catheter Making Machine Mass Production

Multiple Lumen Center Venous Catheter Making Machine Mass Production

About machine:

Medical Center Venous Catheter Extrusion Line is mainly used in the production of ordinary catheter and spring anesthesia catheter and precision medical level of various types, such as reinforced endotracheal intubation catheter, combining with the production equipment and production technology of Mr, catheter has good elasticity, high tensile strength, not easy to fold, the medicine even wait for a characteristic, is the production of multicolor, porous or multilayer precision medical catheter manufacturers the ideal equipment.

Medical anesthesia tube refers to as the disposable anesthesia epidural catheter, catheter use PVC material manufacturing, tube joint use ABS materials manufacturing, product composited by tube and tube joint, mainly applied in clinical surgery epidural anesthesia, and for the patient transfer anesthesia and analgesia liquid medicine.

The special application of anesthesia catheter makes the tube size precision requirements are extremely accurate, usually the allowable tolerance should not more than +/- 0.02 mm.

Machine features:

1. The extruder adopts Siemens man-machine interface and computer control operation system, maintenance-face motor from Germany and driving by decelerator, which can effectively avoid low efficiency and big transmission error of general belt transmission, dust, grease dirt and noise produced during manufacturer process are also avoided.

2. The extruder and haul-off unit adopts complete closed loop servo motor which enables hualing speed to change with the extruder speed, and consequently ensure the speed synchronization on the whole line with high precision and frequency responsibility. It can also prevent pipe diameter from flucuating when working speed is changed due to environmental factors, and thus ensures product precision up to ±0.02mm.

3. The cooling tank is made of SUS304 stainless steel with glass closed structure and the stainless steel centrifugal pump for the special medical grade deionizer water, and the water annulus and low vacuum molding ensures fine roundness and precision of the pipes, the air annulus drying device allows the cooling water to be used circularly and not to splash on the ground.

4. The haul-off unit consists of belt made from Switzerland, servo motor and the controller of Japan Mitsubishi, turbine and worm decelerator from Germany, it can work with high precision and stability and no skidding or noise.

5. The cutting machine is equipped with aluminum alloy rotatable knife arm of low inertia as well as special cutting knife pouch which ensures smooth cuts, it's servo motor driving and PLC of Japan Mitsubishi as well as Siemens man-interface ensure precision of the cutting length, and the cutting length and cutting times can be set and counted by automatically.

Extruder SHSJ-45

| Diameter | 45mm |

Screw L/D | 25-30 | |

Nitriding of screw | One week for nitriding | |

Motor power | 7.5kw | |

Brand of Temperature Control System | Japanese OMRON | |

Power system | Fujie inverter | |

Motor | Siemens | |

Material | 38 CrMOALA | |

Cooling system | Mechanical structure | Made of SUS304 stainless steel |

Three-dimensional regulating system | Rail regulation | |

Centrifugal pump | Medical grade deionized special stainless steel | |

Haul-off | PU flexible multi wedge belt | |

Power : 1.5kw | ||

Cuter/winder | Power : 5kw | |

Warranty & Service :

1. One year warranty, subject to the proper use during this period, free spare parts are available to replace to replace the mal-function parts due to our material defects, delivery freight for the parts is borne by the buyer.

2. Free Technical support, our engineers will provide you professional technical support by mail, or phone in 24hrs .

3. According to buy's requirements, we can offer installation, commissioning and training to your personnel at your country if necessary.

4. The buyer should pay for air ticket (to and fro), accommodation, daily transportation to and from (hotel to factory) and return to our technicians, also the buyer should pay USD 50.00 for each technician.

5. If you need our workers to install and test in your factory , it is the responsibility of the buyer to obtain all necessary working permits in accordance with buyer country law and rules.

6. All standard utilities example power 380V, 3 Phase, necessary water for cooling and compressor air are to be provided by buyer at no cost to us.

7. All necessary electrical power cables and connection to the extruder granulator machine are to be provide by the buyer.

8. We will not be held liable for any irregular power connections which resulted in our machine faulty/damages.

Remark :

You are warmly welcome to our factory to learn how to running this machine, from installation and how to maintain this machine for free.